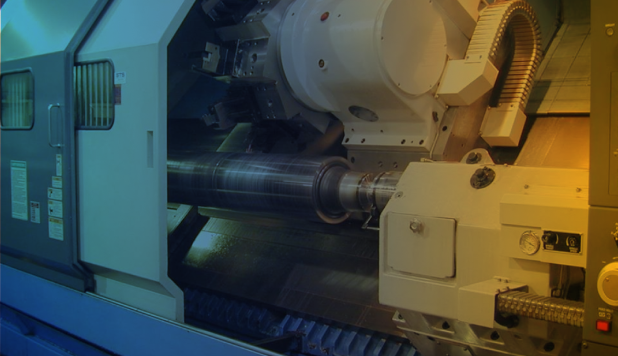

For over forty years, Kocsis has been the premier choice for roll refurbishment, manufacturing, and related services. Using our specially-designed weld cladding equipment, multiple proprietary wires, and custom in-house weld processes, we provide steel roll repairs with consistent microstructures, chemistries, and hardnesses that result in outstanding performance and superior value. From premier individual roll refurbishment to value-added services such as transportation, inventory management, assembly, and engineering support, Kocsis Rolls+ delivers superior quality and service from the first receipt to final inspection.

click on Process to view details