We do big-time rewarding work. And you can, too. At Kocsis, we know it takes the right blend of talent, knowledge, service, and experience to tackle the biggest and toughest jobs. Whether you’re a current student, recent graduate, or seasoned professional, there’s a good chance we have an opportunity that’s just right for you.

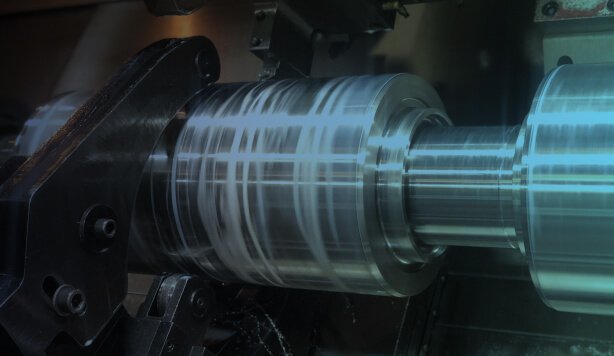

From CNC machinists, welders, engineers, and assembly technicians; to sales, administration, supply chain, and more, the Kocsis campuses in Alsip, IL, and Northwest Indiana offer numerous positions across our divisions. Discover rewarding work in partnership with a wide variety of industries and harness your individual talents and skills, to build a brighter tomorrow. Check out our manufacturing jobs and available openings to find your fit.

Kocsis is an Equal Opportunity Employer that does not discriminate on the basis of actual or perceived race, color, creed, religion, national origin, ancestry, citizenship status, age, sex or gender (including pregnancy, childbirth and pregnancy-related conditions), gender identity or expression (including transgender status), sexual orientation, marital status, military service and veteran status, physical or mental disability, genetic information, or any other characteristic protected by applicable federal, state or local laws and ordinances. Kocsis Brothers Machine Company and Kocsis Technologies’ management team is dedicated to this policy with respect to recruitment, hiring, placement, promotion, transfer, training, compensation, benefits, employee activities, access to facilities and programs and general treatment during employment. The Company will endeavor to make a reasonable accommodation of an otherwise qualified applicant or employee related to an individual’s: physical or mental disability; sincerely held religious beliefs and practices; and/or any other reason required by applicable law, unless doing so would impose an undue hardship upon the Company's business operations.